March 22, 2022

J. Alex Swift started knitting alpaca socks 25 years ago and are still going strong. That means the company started way before the alpaca craze, way before people knew the benefits of the fibre or had the chance to buy alpaca products in the UK.

So how did it start and what was the risk involved?

I sat down with Neil Swift, one of the directors of the company to get a history lesson. It made sense to interview him since Neil was the one who decided to develop alpaca socks.

“It was not long after I took over the company from my father. One of our wholesale customers was enquiring if we can make socks out of an exotic fibre. The alpaca yarn fitted in Swift’s profile with the luxury socks we were already making.”

Once there was a booming textile industry in the UK, the hub being in Leicestershire. However, as world trading advanced, companies commissioned their socks from abroad. That meant cheaper products and often poor quality too, not even considering the health benefits of a great pair of socks.

J. Alex Swift has a history of knitting things out of the ordinary. That is exactly why the factory is still here after 125 years. Slowly but surely the textile manufacturers went out of business in Leicestershire. The ones still standing all specialise something bespoke such as football socks, school socks or dance socks. In Swift’s case, it’s alpaca bed socks and walking socks.

It wasn’t easy to start, and it isn’t easy today.

The first sock was 100% alpaca. The fabric was falling apart after a few wears. 100% alpaca fabric would be more suitable as a scarf or a jumper, but a sock needs to endure constant friction. With experimentation, a fabric was engineered to be wearable, durable while keeping the lovely feel of the alpaca fibre. After a few tries, a yarn has been developed that brought satisfactory performance.

Following a successful first run, it was time to take the big leap, developing an alpaca range and offering it wholesale. When you decide what yarn is the right yarn you have to buy it in significant quantities to persuade anyone to spin it to your specification. And as you can imagine alpaca yarn is not cheap. Then you wait 4 months for it to arrive. It involves a long lead time because the best place to manufacture the alpaca yarn is in Peru where the alpacas are indigenous and the industry of handling the fibre is 1000s of years old.

When the yarn finally arrives you still have to knit it, toe-close it, get it dyed, wash it and press it. Then you have a brilliant product. You have then made a range of alpaca socks with no certainty of customers. 25 years ago, it wasn’t a common, well-known – and not yet a sought after – fibre. You had no idea who – if anyone – would buy it until you offered it to them.

Be visionary, be bold

“The risk was enormous but one of the best decisions I ever made. In every successful business, there is a huge risk involved at one point or another. If it wasn’t like that everyone would make the same tried and tested products.”

Neil also added that Swift had a good experience with developing mohair products which became a successful part of the business, therefore they believed if they could develop an alpaca yarn that was suitable for socks there was a possibility for the same success.

Nowadays alpaca socks are 45% of the business so we can safely say it worked.

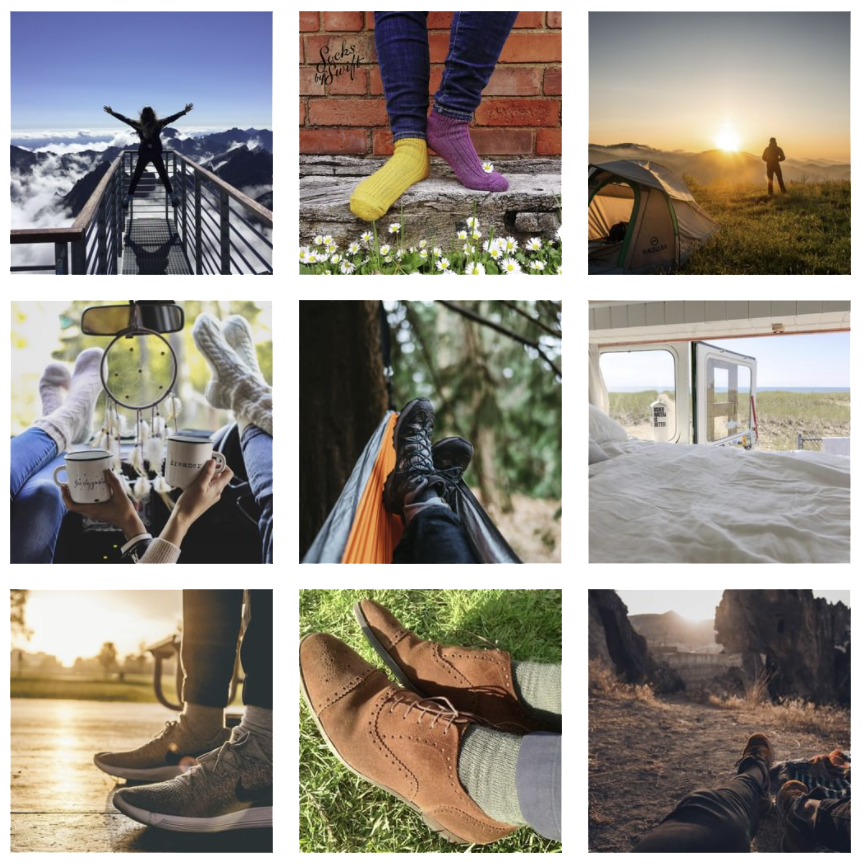

The alpaca range started fairly small, and it gained momentum and had a snowball effect. All that without any type of advertisement or any salesperson. While having great fibre is key, it is not enough. You need to produce socks for specific activities people are looking for, like the top of the range of alpaca walking socks Swift offers.

Traditional vs. Modern

J. Alex Swift have traditional ribbed machinery -, many with cushioned sole facilities – which shows off the luxurious alpaca yarn perfectly. In some ways better than a modern machine that often needs extra elastic to make a sock.

Many modern machines are single-cylinder, rather than ribbed machines. These machines produce plain knit, everyday socks that you can buy for pennies. They usually have an imitation ribbed top, which is a “mock” rib as there are lots of elastic that goes into the fabric to mimic what a ribbed machine can do without any elastic.

“…with rib machines, we don’t have to put the excessive elastic in the top or anywhere in the rib.”

It is a lovely product. And J. Alex Swift sells it in a way that small, independent shops can buy it, without demanding a large order. Supporting small British businesses just as Swift itself.

“When we opened the retail side of the business, we wanted our products to be slightly different from what we offer wholesale to distinguish from customers buying from us directly or other wholesale sources. Also, not to compete with our current wholesale customers to maintain the confidence and good partnerships which have been built over time.”

For example, the best seller alpaca bed socks in beautiful contrast colours are exclusively available on the Socks by Swift website.

Despite all the success and now with a growing retail side, sock manufacturing has its difficulties today as much as it did a few decades ago. Retaining the skills necessary to make socks in an industry that is now small and still shrinking is only one of the hardships.